Siting the kilns

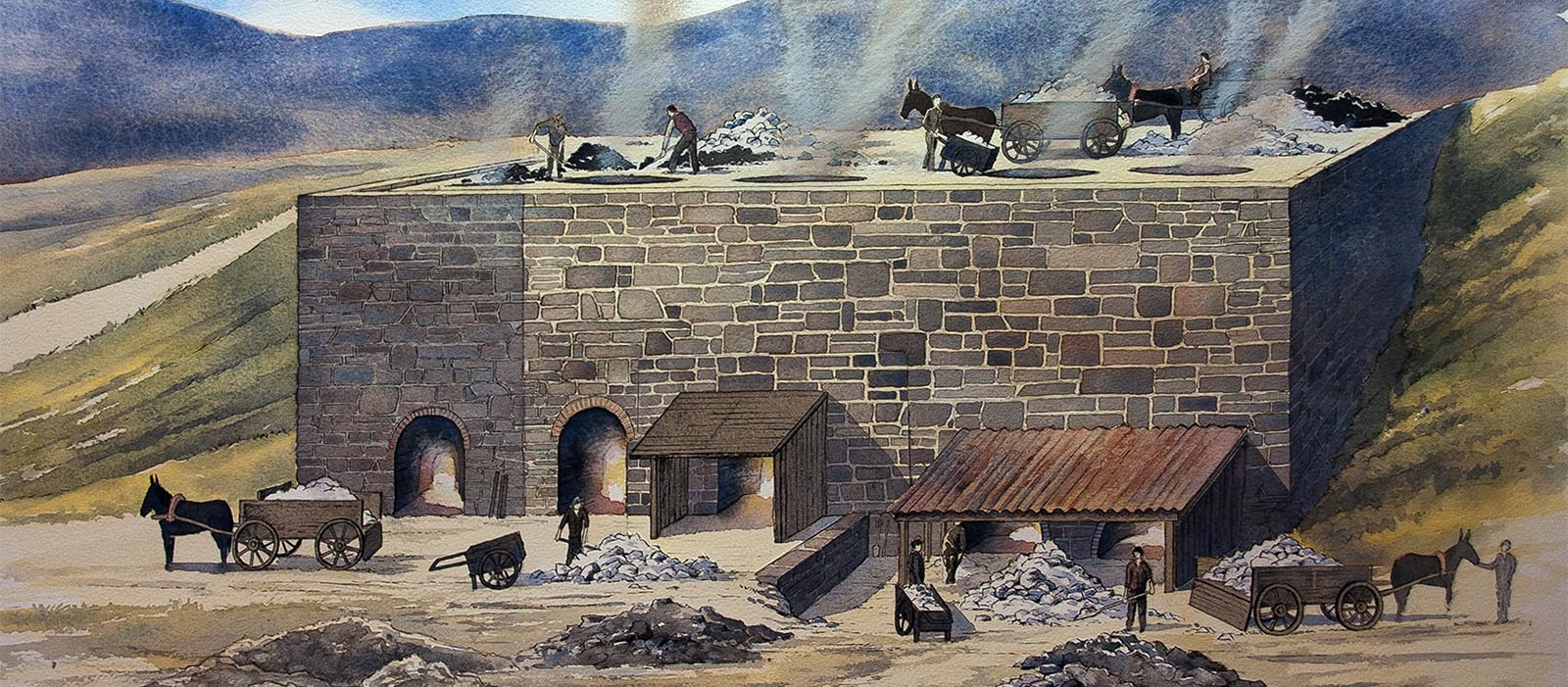

Limekilns were sited close to a quarry and built into a slope where possible so that that it was easy to load the kiln from the top and take the lime away from the bottom. The outer shells of the kilns were built in local limestone but they were lined with fire-brick or harder stone that could withstand the intense heat.

Siting the kilns

Raw Materials

Limestone was quarried from just behind the kilns while coal was brought by wagon from the Flintshire coast. Not all the limestone on Halkyn is the same. Aberdo limestone produces hydraulic lime that sets under water and is used in the construction of bridges and docks.

Raw Materials

Loading the kiln

Lumps of limestone and coal were loaded in layers. It takes two tons of freshly quarried limestone and half a ton of coal to make one ton of lime.

Loading the kiln

Burning

Wooden kindling was used to light the fire at the bottom and gradually the temperature would increase to around 1000˚C, hot enough to change the limestone into lime.

Burning

Unloading

After 4 – 5 days hot, crumbly lime was raked out of the hearth at the bottom and loaded into wagons. It was hard, physical work that had to be done carefully as lime is highly caustic and can cause horrific burns.

Unloading